OUR EXPERTISE

Cold forming

Cold forming, the company's core business, brings many advantages:

• Little or no loss of material in the production of parts, • High production rate, commonly more than one part per second,

• Increased resistance thanks to the fibers that follow the contour of the parts,

• Improved mechanical characteristics by strain hardening the material,

• Good geometric, dimensional and surface finish precision.

Rolling process

Complementary to cold forming, it offers the same advantages:

• No material loss,

• High production rate,

• Increased resistance thanks to the fiberization which follows the contour of the thread,

• Improved mechanical characteristics at the bottom of the thread,

• Good geometric and dimensional precision.

Heat treatment

It makes it possible to reinforce and standardize the mechanical characteristics of the parts.

- Our resources allow us to carry out the following processing:

• quenching/tempering,

• Carburizing,

• Carbonitriding.

Machining and grinding

Our machining equipment is suitable for finishing our blank parts.

SFF has sets of robot that offer multiple possibilities:

• High-speed CNC machining,

• Automatic feeding,

• Automatic tool changes,

• Auto control.

Long tapping operations are made on-site as well.

SFF also uses its grinding machines to achieve micron dimensional accuracy.

These combined resources allow SFF to offer the best technical and economic compromise to its customers.

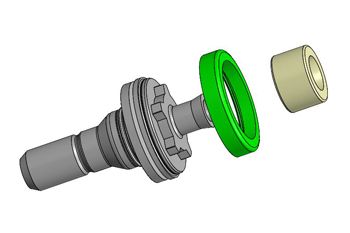

Component assembly

Some particular parts design lead us to use automated assembly equipment.

These machines allow :

• Assembly and crimping of several mechanical parts,

• Self-checking of assembly functions

Surface treatments

SFF uses the best solutions available on the market to meet a wide variety of parts processing requirements, such as:

• A particular color

• Mechanical requirements (thread lock, coefficient of friction, etc.)

• Resistance criteria (corrosion, etc.)

Final control - Packaging

SFF integrates automated sorting

devices in order to guarantee 0 defects on

the requested characteristics. These machines

are coupled with automated packaging.

Our equipment make it possible to carry out 100% checks on:

- Material health by Eddy current,

- Dimensions by camera,

- Presence of elements assembled by Poka Yoke,

- Marking or pairing by camera.

ALTENLOH BRINCK & Co

ABC UNTERNEHMENSGRUPPE SINCE 1823